- Optomechanics

- Precision Optics

- Optics Software

- Lightsources & Laser

- New Products

LM1 Optic Mount

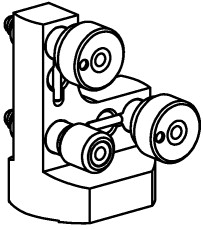

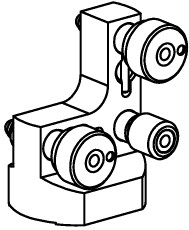

Unique aluminum base design

The solid LM1 optic mount base and plate are machined from aluminum alloy and are protected with a non-shiny black aluminum oxide coating known as anodize. The unique design of the base is more rigid and has a higher frequency than flat mounts. The LM1's wide bottom provides superior mounting to tables or accessories. Thus, greater stability with less susceptibility to vibration.

Stainless steel adjustment screws in phosphor bronze bushings

The LM1 is equipped with three 10-80 adjustment screws each with 0.175 in. of travel minimum. The adjustment screws are considered to have the finest resolution available today.

Dynamic range

The LM1 mount can be angularly adjusted to more than ±12.5° which leads to a beam deflection of ±25°.

Sapphire hard seat technology

We use a large 3/16 x 0.034 in. sapphire flat polished to optical standards on all LM1 mounts. The hard cylindrical vee is also standard on all LM1 mounts. These seats are so tough, they have been known to work flawlessly even when the mount has been dropped.

Nylon tipped set srews

Kinematically locates the optics and secures it without stressing or damaging it. They also allow for easy removal and replacement.

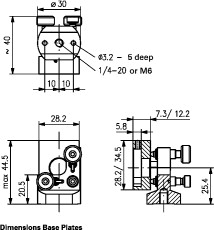

1/4-20 or M6 mounting hole

We provide the largest and strongest mounting holes to ensure stability. Deflections are solely the result of material elasticity.

Krytox fluorinated lubricant

Krytox greases have vapor pressures of 8 x 10-8 to 6 x 10-9 torr at 30 °C (100 °F) according to Du Pont and thus are unlikely to outgas on your expensive optics. Krytox also has a high degree of chemical inertness and outstanding oxidation resistance. Therefore, the adjustment screws will maintain their original smooth feeling if used daily, monthly, or yearly.

Metric

The standard mounting hole in the base is M6. The top set screw in the front plate is 4-40 UNC or 6-32 UNC.

-

- For highest demands

- Unique aluminium base design

- High dynamic range

- Sapphire hard seat technology

- For optics with 0.5" or 1.0" diameter

Front plate for 0.5“ Optic; Offset-Right or Offset-Left

Front plate, plain without hole

Front plate for 0.5“ Optic

Front plate for 1.0“ Optic

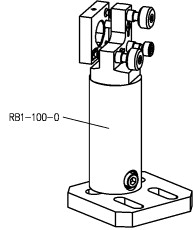

LM1-4021-0 and RB1-100-0

Left L-type

Right L-type

| Part Number | Product Description | Price | Available | Quantity | To Cart |

LM1 Optic Mount

| Part No. | Optic Size (mm) | Front plate | Basis | Spindle Pitch | Threads / Boreholes | Material / Finishing |

| G404333000 | Ø12.7 | for 0.5'' Optic | Left L-type | 0.3175 mm | M6 | Black Anodized Aluminum |

| G404334000 | Ø25.4 | for 1.0'' Optic | Left L-type | 0.3175 mm | 1/4-20UNC | Black Anodized Aluminum |

| G404338000 | Ø12.7 | for 0.5'' Optic; Offset-Right | Left L-type | 0.3175 mm | 1/4-20UNC | Black Anodized Aluminum |

Order Catalog

Order Catalog